Transporting Trees in Tenryu Forest

Lumberjack Activity Report #2

Four months after our first lumberjack experience, we returned to meet Maeda san, the lumberjack, in Kicoro Forest, Tenryu Ward, Hamamatsu City, Shizuoka Prefecture.

This time, we carried the cedar trees we had cut down ourselves, following the traditions of those who came before us, and sawed them into boards. The experience was exciting and full of new discoveries—almost as if we were bringing the distant “forest” closer to our everyday lives.

March 26, 2021

The weather in Tenryu was perfect. Under a hazy spring sky, the Mitsumata tree’s flowers were in bloom, signaling the arrival of the season. Our team had grown: five members from last time plus six newcomers, making a total of eleven.

The day’s tasks were challenging—transporting logs, experiencing sawmilling, and even splitting firewood. It promised to be a hard but rewarding day.

Following the Ancestors

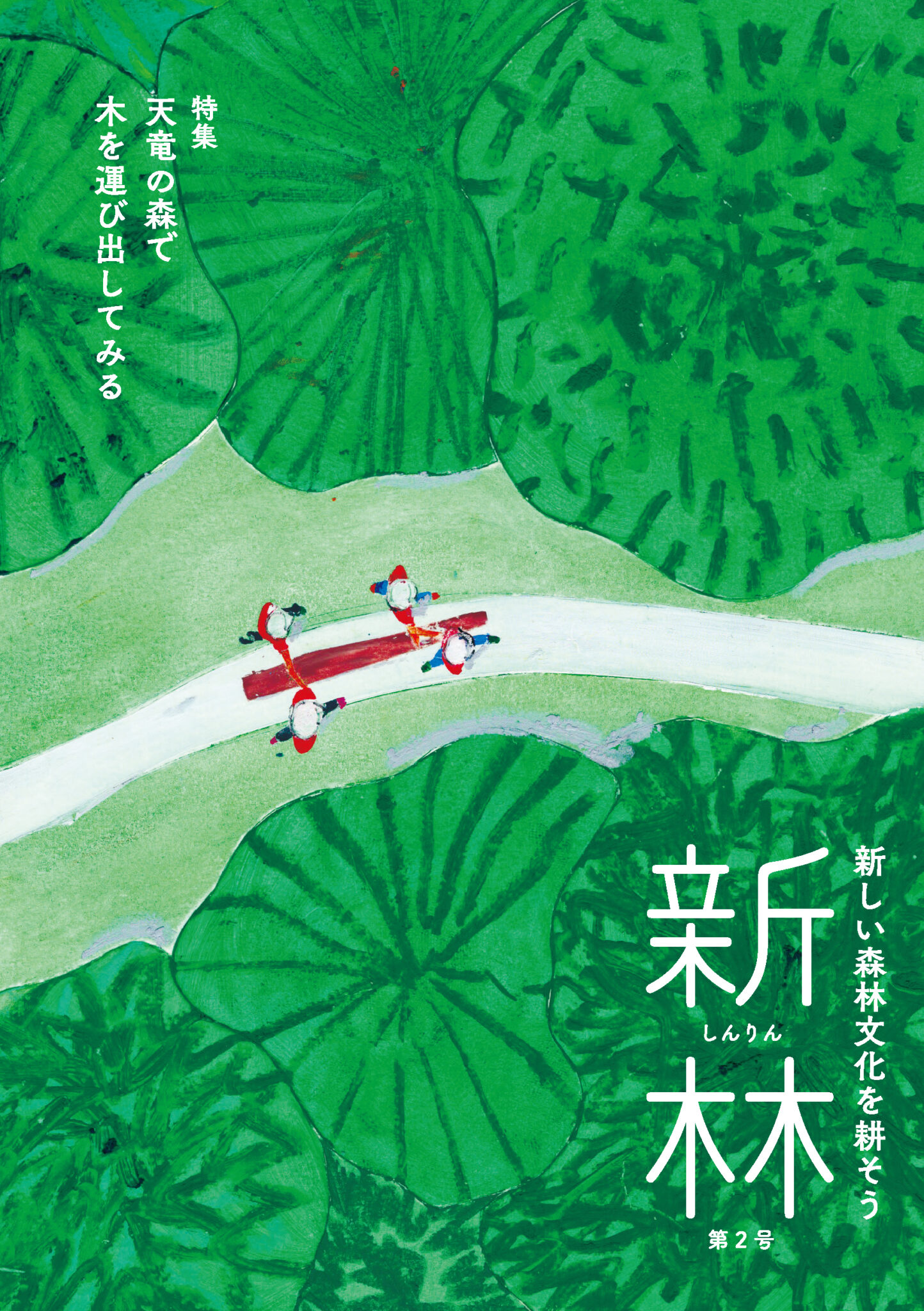

Since ancient times, logging has relied on manual labor. Even today, with advanced forestry machines available, there are still moments when logs must be carried or rolled by hand. On this day, we experienced the fundamentals of lumberjacking—transporting trees manually without machines.

In the middle of the forest, a log about four meters long lay before our team. Nearby were ropes, wide sling belts, and hooks prepared by Maeda san.

“Today, let’s use not only our strength but also our brains,” he said. “Think about the choice and use of tools, the direction of the logs. I won’t tell you what’s correct—figure it out yourselves.”

With that brief instruction, the team split into three groups and began brainstorming ways to move the log.

“Wow! Just having this one rope makes a big difference,” someone exclaimed as the discussion turned lively. Everyone tested the tools and shared ideas on the best way to transport the heavy timber.

Cedar and Leaf Drying

Even logs of the same length can differ in weight. It’s not just about thickness—the time since the tree was felled matters too.

Cedar trees, for example, have a high moisture content. After cutting, they are left for several months to allow the water to drain. The cedar we cut last time still holds moisture, which is why its branches and leaves remain green. When the leaves begin to wither, it signals that most of the water has drained.

This process is called “leaf drying.” In the past, people would wait for this stage to make the wood as light as possible before transporting it. Cypress, on the other hand, contains less moisture than cedar, so it’s lighter even before drying. Once dried, cedar becomes significantly lighter and easier to handle.

Tough Transport Work on Steep Slopes

Kicoro Forest has many trees growing on steep slopes, making both felling and transporting logs dangerous. The ground was unstable, and workers had to be very careful.

Logs near the work path were moved smoothly, but those farther away were much harder to transport. Our team said things like:

- “I can’t put any strength into it.”

- “The person in front looks like they’ll fall with the log.”

- “Maybe it’s better to pull only from the front instead of both ends.”

- “This feels like walking a dog!”

We tried many methods—lifting with ropes, carrying on shoulders, and dragging with ropes. After a lot of effort, we finally finished the job.

Trying to Saw the Wood

In the afternoon, it was finally time for sawmilling. We used a simple setup—a chainsaw with a sawmilling attachment—so we could work right on-site.

The person operating the saw wore gloves, a helmet, earmuffs for noise protection, and protective clothing from the waist down. Holding the handle, they slowly moved along the guide. Sawdust flew up as the loud sound echoed through the forest. It took over 30 minutes to saw just one board, with everyone taking turns.

While waiting, others split firewood. They lowered their hips, swung the axe, and kakoon!—a satisfying sound rang out when the wood split. The unexpected excitement and sense of accomplishment were impressive.

From Logs to Boards

When all the work was finished, Maeda san showed us the cross-section of the wood—like opening the lid of a box. The freshly cut surface was still moist, with a beautiful pinkish-brown gradient.

“It feels smooth and nice.”

“It smells good.”

“I want to take it home.”

“I suddenly feel attached to it.”

The lumberjack team gathered around the single board, touching it as if admiring a newborn baby. We were amazed by the simple yet powerful transformation from a log to a board. This was the biggest takeaway of the day.

[Today’s Teacher] Tsuyoshi Maeda, Lumberjack/Representative of Kicoro

Since moving to Tenryu in 2003, Maeda san has dedicated himself to forestry. He also works to share the beauty and importance of forests through activities like FUJIMOCK FES, where participants experience everything from cutting trees to crafting wood items. In addition, he gives lectures at schools to inspire the next generation.

Thoughts and Beyond

Relay column by NCM employees Participating in the Lumberjack Activities

This year, a lot of wood will be used in various venues—starting with the 2,600㎥ at the Ariake Gymnastics Center, where Nikken Sekkei participated, and including the Athletes’ Village Plaza and more. At this timing, I joined the “lumberjack activities.”

We transported trees from the forest. It sounds simple, but without paved roads or heavy machinery, manually moving logs was tough. At the same time, it felt refreshing—invigorating my body after long days of working from home. Experiencing it firsthand gave me a new perspective.

As a designer, I thought I knew wood well, having worked on traditional public halls. But by taking part in the process before wood becomes a material, I felt a stronger connection to it.

There are still many steps before wood can be put to use. I hope to keep contributing to the proper use of wood and the cultivation of forest culture through these activities.

Takeshi Yasuoka

Director, Nikken Sekkei Construction Management (NCM)